Specialist for the rubber industry, product professional for carbon blacks

Under the brand name LUVOMAXX® we combine a unique range of services for the rubber industry together with our almost 100 years of experience with carbon blacks as a product. Through our worldwide and independent sourcing of raw materials, we offer you economically and technically optimized solutions that we adapt to your processing requirements and produce for you in customized form.

Styrene-Butadiene Rubber (ESBR)

| Emulsion Styrene Butadiene Rubber (ESBR) | Grade | Styrene (%) | Viscosity ML (1+4) 100°C | Oil Content phr |

|---|---|---|---|---|

| Europrene® | 1500 | 23,5 | 52 | - |

| Europrene® | 1502 | 23,5 | 52 | - |

| Europrene® | 1502 F | 23,5 | 52 | - |

| Europrene® | 1509 | 23,5 | 35 | - |

| Europrene® | 1723 | 23,5 | 50 | 37,5 TDAE |

| Europrene® | 1739 | 40 | 52 | 37,5 TDAE |

| Europrene® | 1783 | 23,5 | 50 | 37,5 RAE |

| Europrene® | HS 630 | 63 | 56 | - |

Solution Styrene Butadiene Rubber (SSBR)

| Solution Styrene Butadiene Rubber (SSBR) | Grade | Styrene (%) | Vinyl (%) | Viscosity ML (1+4) 100°C | Oil Content phr |

|---|---|---|---|---|---|

| Europrene® | SOL B 1205 | 26 | 50 | - | |

| Europrene® | SOL R 72614 | 25 | 64 | 55 | 37,5 TDAE |

| Europrene® | SOL R C2525 | 26 | 24 | 54 | - |

Polybutadiene Rubber (BR)

| High Cis Grades | Cis (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| Europrene® NEOCIS BR 40 | 97 | 43 |

| Europrene® NEOCIS BR 60 | 97 | 63 |

| Low Cis Grades | Cis (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| INTENE® 50 | 38 | 48 |

| High Vinyl Grades | Vinyl (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| EUROPRENE® BR HV80 | 77 | 70 |

Thermoplastic Rubber (TPR)

| Styrene-Butadiene (SBS) - dry - | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SBS EUROPRENE® SOL T 166 | Linear | 30 | 10 |

| SBS EUROPRENE® SOL T 6205 | Radial | 25 | 10 |

| SBS EUROPRENE® SOL T 6302 | Linear | 30 | 12 |

| SBS EUROPRENE® SOL T 6320 | Linear | 31 | 75 |

| SBS EUROPRENE® SOL T 6414 | Radial | 40 | 22 |

| Styrene-Isoprene (SIS) | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SIS EUROPRENE® SOL T 190 | Linear | 16 | 25 |

| SIS EUROPRENE® SOL T 9113 | Linear | 18 | 8 |

| SIS EUROPRENE® SOL T 9133 | Linear | 16 | 55 |

| SIS EUROPRENE® SOL T 9133 | Linear | 16 | 55 |

| SIS EUROPRENE® SOL T 9326 | Linear | 30 | 15 |

| Styrene-Ethylene-Butylene (SEBS) | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SEBS EUROPRENE® SOL TH 2311 | Linear | 30 | - |

| SEBS EUROPRENE® SOL TH 2312 | Linear | 30 | - |

| SEBS EUROPRENE® SOL TH 2314 | Linear | 31 | - |

| SEBS EUROPRENE® SOL TH 2315 | Linear | 32 | - |

Ethylene-Propylene Rubber EP(D)M

| Copolymer | Propylene Content (% wt) | Viscosity Mooney ML (1+4) 125°C | Oil Content (% wt) |

|---|---|---|---|

| DUTRAL® CO 034 | 28 | 44 | - |

| DUTRAL® CO 038 | 28 | 60 | - |

| DUTRAL® CO 043 | 45 | 33 | - |

| DUTRAL® CO 054 | 41 | 44 | - |

| DUTRAL® CO 058 | 48 | 80 | - |

| DUTRAL® CO 059 | 41 | 79 | - |

| Terpolymer | Propylene Content (% wt) | Viscosity Mooney ML (1+4) 125°C | Oil Content (% wt) | ENB (%) |

|---|---|---|---|---|

| DUTRAL® TER 4033 | 25 | 30 | - | 5 |

| DUTRAL® K TER 4033 | 25 | 30 | - | 5 |

| DUTRAL® TER 4038 EP | 27 | 60 | - | 4.4 |

| DUTRAL® TER 4039 | 27 | 77 | - | 4.4 |

| DUTRAL® TER 4044 | 35 | 44 | - | 4 |

| DUTRAL® TER 4047 | 40 | 55 | - | 4.5 |

| DUTRAL® TER 4049 | 40 | 76 | - | 4.5 |

| DUTRAL® TER 7040 | 40 | 87 | - | 6.5 |

| DUTRAL® TER 4334 | 27 | 28 | 30 | 4.7 |

| DUTRAL® TER 4436 | 28 | 43 | 40 | 5.5 |

| DUTRAL® TER 4437 | 32 | 57 | 40 | 4.5 |

| DUTRAL® TER 4437 WO | 32 | 57 | 40 | 4.5 |

| DUTRAL® TER 4535 | 32 | 32 | 50 | 3.4 |

| DUTRAL® TER 4548 | 36 | 47 | 50 | 4.5 |

| DUTRAL® TER 6537 | 32 | 43 | 50 | 8 |

| DUTRAL® TER 9046 | 31 | 67 | - | 8.9 |

Acrylonitrile Butadiene Rubber (NBR)

| Standard types | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE® N 2845 | 28 | 45 |

| EUROPRENE® N 2860 | 28 | 60 |

| EUROPRENE® N 3330 | 33 | 30 |

| EUROPRENE® N 3345 | 33 | 45 |

| EUROPRENE® N 3360 | 33 | 60 |

| EUROPRENE® N 3380 | 33 | 80 |

| EUROPRENE® N 3945 | 39 | 45 |

| EUROPRENE® N 3960 | 39 | 60 |

| EUROPRENE® N 3980 | 39 | 80 |

| EUROPRENE® N 4560 | 45 | 60 |

| Green types | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE® N 1934 GRN | 19 | 45 |

| EUROPRENE® N 2830 GRN | 28 | 30 |

| EUROPRENE® N 2845 GRN | 28 | 45 |

| EUROPRENE® N 2860 GRN | 28 | 60 |

| EUROPRENE® N 3330 GRN | 33 | 30 |

| EUROPRENE® N 3345 GRN | 33 | 45 |

| EUROPRENE® N 3380 GRN | 33 | 80 |

| EUROPRENE® N 3945 GRN | 39 | 45 |

| NBR-PVC Blends | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE® N OZO 7028 | 19,5 | 75 |

| EUROPRENE® N OZO 7028/60 | 19,5 | 60 |

| EUROPRENE® N OZO 7033 | 23 | 75 |

| EUROPRENE® N OZO 7033/60 | 23 | 60 |

| EUROPRENE® N OZO 7039 | 27 | 75 |

Latex (SBR, XSBR, NBR)

| Styrene Butadiene Latex | Styrene (%) | Brookfield Viscosity (20 rpm, 25°C, mPa.s) |

|---|---|---|

| EUROPRENE® Latice 5570 | 26 | 800 |

| EUROPRENE® Latice 5577 | 30 | 800 |

| EUROPRENE® Latice 2430 | 35 | 1100 |

| Carboxylated Styrene Butadiene Latex | Styrene (%) | Brookfield Viscosity (20 rpm, 25°C, mPa.s) |

|---|---|---|

| EUROPRENE® Latice 405 | 40 | 300 |

| EUROPRENE® Latice 406 | 40 | 300 |

| EUROPRENE® Latice 440 | 60 | 300 |

| EUROPRENE® Latice 455 | 47 | 300 |

| EUROPRENE® Latice 5583 | 40 | 300 |

| EUROPRENE® Latice 5584 | 60 | 400 |

| EUROPRENE® Latice 5585 | 47 | 300 |

| EUROPRENE® Latice 5587 | 75 | 600 |

| EUROPRENE® Latice 5588 | 50 | 350 |

| EUROPRENE® Latice 8435 | 69 | 600 |

| EUROPRENE® Latice 8487 | 67 | 500 |

| Acrylonitrile Butadiene Latex | ACN (%) | Brookfield Viscosity (20 rpm, 25°C, mPa.s) |

|---|---|---|

| EUROPRENE® Latice 2620 | 38 | 30 |

Polyisoprene (IR)

| Polyisoprene (IR) | Tg | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| ISOGRIP (60% 3,4 - IR) | -11°C | 70 |

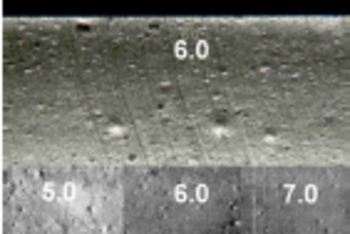

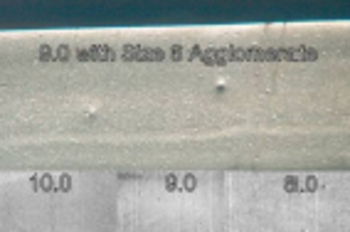

Furnace blacks

LUVOMAXX BC Tread Grades

| ASTM | N-110* | N-115 | N-121* | N-134* | N-220 | N-234 | N-326 | N-330 | N-339 | N-347 | N-375 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Appearance | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | |

| Adsorption DBP (ml/100g) | D 2414 | 113 | 113 | 132 | 127 | 114 | 125 | 72 | 102 | 120 | 124 | 114 |

| Iodine no. (mg/g) | D 1510 | 145 | 160 | 121 | 142 | 121 | 120 | 82 | 82 | 90 | 90 | 90 |

| Ash (% max.) | D 1506 | 0,7 | 0,7 | 0,7 | 0,7 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 |

| Volatiles (% max.) | D 1514 | 3,0 | 3,0 | 3,0 | 3,0 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 |

| Bulk density (kg/m2) | D 1513 | 345 | 345 | 320 | 320 | 355 | 320 | 455 | 380 | 345 | 335 | 345 |

(*) Specific grades supplied only on request

LUVOMAXX BC Carcass grades

| ASTM | N-550 | N-550 LG* | N-650 | N-660 | N-762** | N-772 | |

|---|---|---|---|---|---|---|---|

| Appearance | Pellets | Pellets | Pellets | Pellets | Pellets | Pellets | |

| Adsorption DBP (ml/100g) | D 2414 | 121 | 121 | 122 | 90 | 65 | 65 |

| Iodine no. (mg/g) | D 1510 | 43 | 43 | 36 | 36 | 27 | 30 |

| Ash (% max.) | D 1506 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,75 |

| Volatiles (% max.) | D 1514 | 1,5 | 1,0 | 1,5 | 1,5 | 1,5 | 1,0 |

| Bulk density (kg/m2) | D 1513 | 350 | 360 | 360 | 420 | 374 | 500 |

(*) LG: Low grit; sieve residue (325 mesh): 15 ppm max.

(**) Specific grades supplied only on request

Thermal blacks

LUVOMAXX Thermal blacks

| ASTM | MT N-990 | MT N-991 | N-772 | |

|---|---|---|---|---|

| Appearance | Pellets | Powder | Pellets | |

| Adsorption DBP (ml/100g) | D 2414 | 40 | 40 | 65 |

| Iodine no. (mg/g) | D 1510 | 8 | 8 | 29 |

| Ph value | D 1512 | 9 | 9 | |

| Ash (% max.) | D 1506 | 0,1 | 0,1 | 0,4 |

| Sieve residue (325 mesh, ppm) | D 1514 | 27 | 34 | 200 |

| Bulk density (kg/m2) | D 1513 | 500 | 360 | 420 |

- Antioxidants/Antiozonants (as pure substance, polymer-bound preparation and dry liquid preparation)

- Accelerators for sulphur vulcanization (as pure substance, polymer-bound preparation and dry liquid preparation)

- Co-agents for sulphur vulcanization (as pure substance, mineral-oil-bound preparation, polymer-bound preparation and dry liquid preparation)

- Flame retardant additives (as pure substance)

- Adhesion promoters between mineral filler and polymer (as pure substance, carbon-black-bound preparation and dry liquid preparation)

- Resins and resin curatives

- Metal oxides (as pure substance, polymer-bound preparation and mineral-oil-bound preparation)

- Odorants (as dry liquid preparation)

- Special plasticizers (as pure substance, carbon-black-bound preparation and dry liquid preparation)

- Blowing agents (as pure substance, powder blend, polymer-bound preparation and mineral-oil-bound preparation)

- Curing agents (as mineral-oil-bound preparation, polymer-bound preparation and dry liquid preparation)

- Vulcanization retarders (as pure substance and polymer-bound preparation)

Precipitated silica

IQESIL

| Grade | Chemical nature | Appearance | Specific surface (m2/g) |

|---|---|---|---|

| EBROSIL PD | Amorphous precipitated silica, SiO2 | Powder | 180 |

| EBROSIL GR | Amorphous precipitated silica, SiO2 | Pellets | 180 |

| EBROSIL S 125 PD | Amorphous precipitated silica, SiO2 | Powder | 125 |

| EBROSIL S 125 GR | Amorphous precipitated silica, SiO2 | Pellets | 125 |

| EBROSIL H180AT | Amorphous precipitated silica, SiO2 | Powder | 180 |

| EBROSIL SA 60 | Sodium and aluminum silicate, amorphous, precipitated 14,5(Si02) Al2O3, 1,4(Na2O) | Powder | 180 |

LUVOMAXX

| Grade | Chemical nature | Appearance | Specific surface (m2/g) |

|---|---|---|---|

| LUVOMAXX HM 1160 | Precipitated amorphous silica, SiO2 | Powder | 160 |

| LUVOMAXX HM 2160 | Precipitated amorphous silica, SiO2 | Pellets | 160 |

| LUVOMAXX HM 1170 | Precipitated amorphous silica, SiO2 | Powder | 175 |

| LUVOMAXX HM 2170 | Precipitated amorphous silica, SiO2 | Pellets | 175 |

| LUVOMAXX HM 1180 | Precipitated amorphous silica, SiO2 | Powder | 180 |

| LUVOMAXX HM 2180 | Precipitated amorphous silica, SiO2 | Pellets | 180 |

Fumed silica

LUVOMAXX

| Grade | Chemical nature | Appearance | Specific surface (m2/g) |

|---|---|---|---|

| LUVOMAXX HM 150 | Fumed silica, SiO2 | Powder | 150 |

| LUVOMAXX HM 200 | Fumed silica, SiO2 | Powder | 200 |

| LUVOMAXX HM 300 | Fumed silica, SiO2 | Powder | 300 |

| LUVOMAXX HM 380 | Fumed silica, SiO2 | Powder | 380 |

MAGRIS TALC series - natural and surface treated talcs

MISTRON© Talc Series - a functional mineral for rubber

MISTRON© Talc Series products are functional minerals, not simple fillers.

MISTRON© VAPOR products provide the rubber formulator with flexibility to balance the benefits of improved processability with higher product performance. MISTRON© VAPOR products occupy a unique position in the rubber industry and have been used succesfully for more than 50 years.

MISTRON© VAPOR Talc Series - improve your mechanical properties!

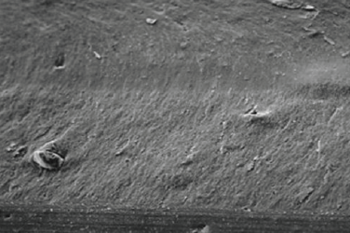

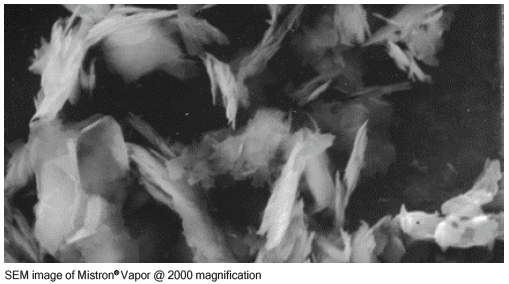

MISTRON© VAPOR is an ultra-fine, micro-lamellar, highly pure, hydreated magnesium silicate specifically developed for the rubber industry. Its platy morphology, organophilic nature, high aspect ratio and surface area result in superior reinforcement and rheology plus permeability resistance for thermoset rubbers.

MISTRON© VAPOR is an extremly soft mineral with a Mohs hardness of one. This property reduces wear on processing equipment compared with other minerals. MISTRON© VAPOR has less than 0.2% absorbed water, which eliminates pre-drying and allows it to be used in liquid-medium cure systems without encountering porosity problems. MISTRON© VAPOR is an electrical insulator and chemically resistant mineral eliminating electrochemical degradation in window seals and hoses plus providing solutions in wire and cable.

MISTRON© VAPOR functions as ...

... Processing Aid providing ...

- Reduced Mixing Times

- Lower Compound Viscosities

- Reduced Heat Generation

- Superior Compound Flow

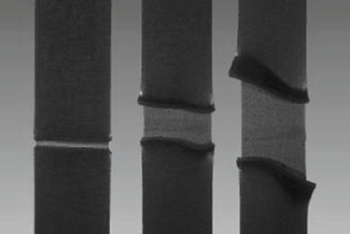

- Improved Extrusion Rate and Quality

- Better Dispersion of Reinforcing Fillers

- Reduced Elasticity / Nerve

- Higher Green Strength

.. Reinforcement improving ...

- Tensile Properties

- Tear Properties

- Fatigue Performance

- Flaw Resistance

- Improved Thermal Performance

- Superior Weathering

... Improvement for wire and cable

- Chemical and Electrochemical Resistance

- Electrical Insulating Properties

MISTRON© HYPERPLATE™ Speciality talc

New Innovative MISTRON© HYPERPLATE™ ULTRA for Superior Barrier Performance

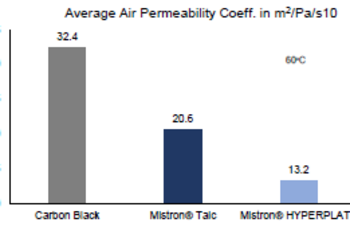

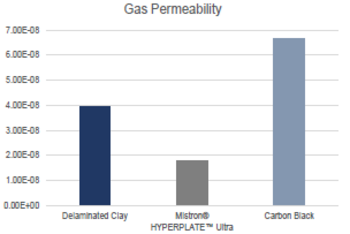

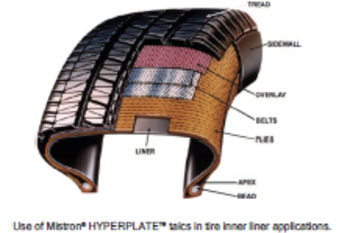

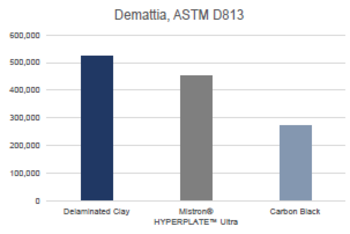

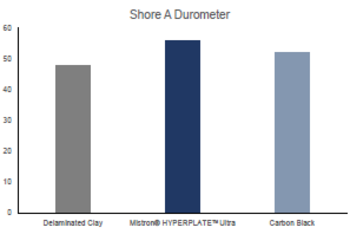

MAGRIS TALC has recently developed a higher aspect ratio HYPERPLATE™ talc for superior barrier performance. In extensive studies multiple talc grades has been tested and MISTRON© HYPERPLATE™ ULTRA was found to be the best performer in Gas Permeability (ASTM D1434) and DeMattia Flex Crack (ASTM D813) against the most commonly used Carbon Black Control and Clay. MISTRON© HYPERPLATE™ ULTRA's gas permeability is 3 times lowerand also sustained about twice the amount of DeMattia Flex Cycles when compared to the Carbon Black Control.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| SILVERLINE© 002 | Natural white powder, bags | Dusting, relase agent talc | Excellent partioning low cost agents | 8,4 | 55 | 75 |

| VERTAL© 92 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 17,5 | 45 | Y72 |

| VERTAL© 97 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (powder) | Natural white powder, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (compacted) | White powder compacted, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR RE | Natural white powder, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness | 2,2 | 31 | 80 |

| MISTRON© VAPOR ULTRA | Natural white powder very fine, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness. Improve extrudate surface quality, enhanced elongation at break | 2 | 12 | 88 |

| MISTRON© CB* | Surface treated powder, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2,2 | 31 | 86 |

| MISTRON© CB6* | Surface treated and finer and densified, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2 | 25 | 88 |

| MISTRON© HYPERPLATETM | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,2 | 8 | 80 |

| MISTRON© HYPERPLATETM ULTRA | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,5 | 10 | 83 |

| MISTROFOAM©* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, foamed polymer products | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2,2 | 31 | 82 |

| MISTRON© ZSC* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance, higher dielectrical stregths, properties in wire and cable | 2 | 25 | 87 |

| MISTRON© TZ2* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2 | 25 | 87 |

| MISTROPHOBE* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, reaktive chemistry with any unsaturated cure system, that enhances hydrophobicity, wet electrical performance and mechanical properties | 2 | 25 | 88 |

* = surface treated

Your personal contact

Business Manager Rubber & Composite Materials